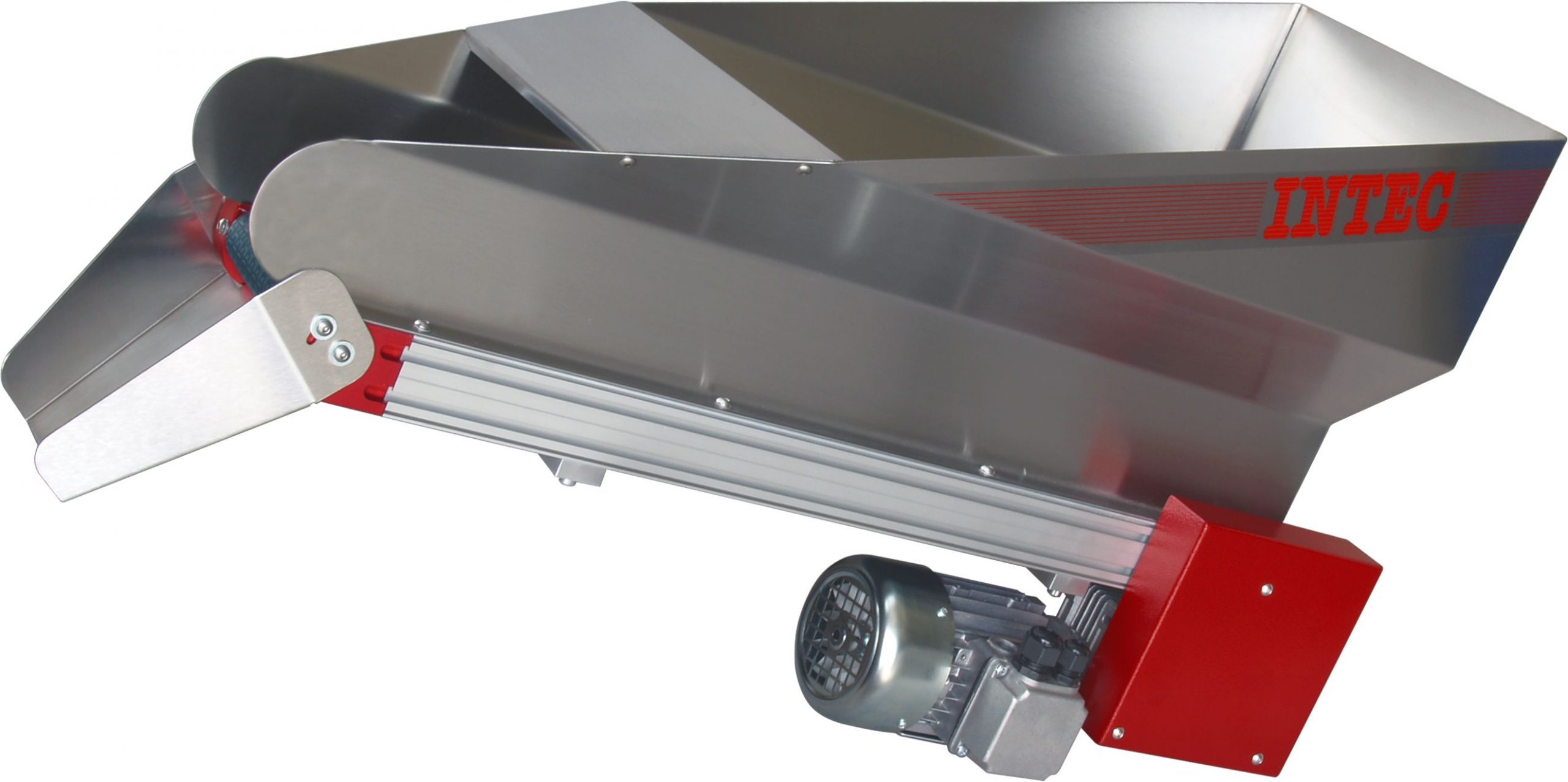

Inclined Hopper- Product Highlights

Ergonomical filling without the need of a pedestal

Inclined hoppers offer the advantage of matching their filling heights to the sorting device. Retrofittung an inclined hopper to an already existing system can easily be done. No additional pedestal is needed. This is an investment that will quickly repay itself.

Not suitable for all kinds of parts

The only disadvantage of inclined hoppers is that they are not suited for all kinds of parts Basic requirement for the use of an inclined hopper is the parts not getting caught in another. Also the parts must be transportable by the conveyor belt at an inclination of 20° – 40°. The conveyor belt will have a high friction coefficient but no studs.

Most shapes of parts can be processed without any problems. Balls, globes, bullets or compression springs made of thin wire are not suitable.

Flexible and adaptable

Extensive adjustment possibilities and variaton options (lateral guides, front panels, drives, …) allow a perfect adaption to your specific requirements.

On top of that we offer a wide range of special equipment and accessories for the belt driven hopper.